-

Anantthe purchase arrived well packaged good service from the provider

Anantthe purchase arrived well packaged good service from the provider -

YadullazadeХорошая цена, хорошее внимание к качеству продукта очень хорошо, короче говоря, все хорошо.

YadullazadeХорошая цена, хорошее внимание к качеству продукта очень хорошо, короче говоря, все хорошо. -

NikolayЯ выкуплю его. Качество продукта очень хорошее.

NikolayЯ выкуплю его. Качество продукта очень хорошее.

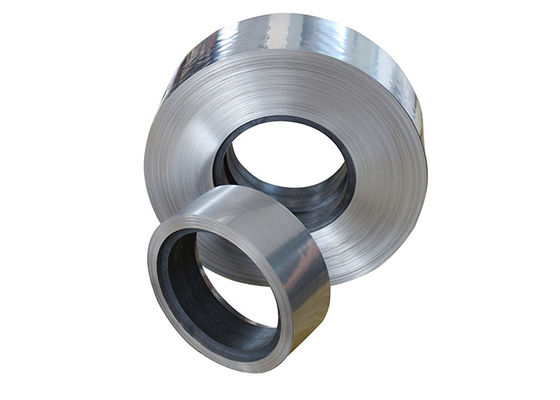

Pyromet 90 High Temperature Nickel Alloy

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Nimonic 90 | Material | Nickel Chromium |

|---|---|---|---|

| Density | 8.18g/cm³ | Melting Point | 1370°C |

| Coefficient Of Expansion | 12.7 μm/m °C (20 – 100°C) | Modulus Of Rigidity | 82.5 KN/mm² |

| Modulus Of Elasticity | 213 KN/mm² 227 / 240 KN/mm² | ||

| Highlight | Udimet 90 High Temperature Nickel Alloy,Nimonic 90 High Temperature Titanium Alloys,Pyromet 90 High Temperature Nickel Alloy |

||

![]()

![]()

- Thermal Spray Wires Alloy

Nimonic 90 Strip is a precipitation hardenable nickel-chromium-cobalt alloy strengthened by the addition of Titanium and Aluminium. Alloy 90 has a high stress rupture strength and creep-resistant at temperatures to 920°C. Nimonic Alloy 90 is typically used in extreme stress applications such as turbine blades, hot working tools, exhaust reheaters, disc and high-temperature springs.

Nimonic 90 is also known as Superimphy 90, Pyromet 90, and Udimet 90.

-

Nimonic 90 Chemical Composition

The chemical composition of Nimonic 90 is given in the following table.

| Element | Content (%) |

|---|---|

| Nickel, Ni | Bal |

| Chromium, Cr | 18-21 |

| Iron, Fe | ≤1.5 |

| Cobalt, Co | 15-21 |

| Titanium, Ti | 2-3 |

| Aluminum, Al | 1.0-2.0 |

| Manganese, Mn | ≤1 |

| Silicon | ≤1 |

| Others | Remainder |

-

Physical Properties

The following table discusses the physical properties of Nimonic 90.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.18 gm/cm3 | 0.296 lb/in3 |

-

Mechanical Properties

The mechanical properties of NIMONIC alloy 80A are tabulated below.

| Properties | ||||

|---|---|---|---|---|

| Condition | Approx. tensile strength | Approx. operating temperature depending on load^^ and environment | ||

| N/mm² | ksi | °C | °F | |

| Annealed | 800 – 1000 | 116 – 145 | – | – |

| Annealed + Aged | 1200 – 1400 | 174 – 203 | up to 550 | up to 1020 |

| Spring Temper | 1200 – 1500 | 175 – 218 | – | – |

| Spring Temper + Aged | 1500 – 1800 | 218 – 261 | up to 350 | up to 660 |